I-Sodium Hydroxide (NaOH), i-aka caustic soda okanye i-lye, yinxalenye ebalulekileyo kwiinkqubo ezininzi zemizi-mveliso, ingakumbi engenakuthintelwa ekuvelisweni kwezinto zokuxutywa, iiplastiki, izonka, amalaphu, ii-inki, amayeza kunye neepigments. NgokuchanekileyoUxinzelelo lwe-NaOHzizinto ezibalulekileyo eziphembelela umgangatho wemveliso.

Ugxininiso lwe-NaOHinobunzima bonyango lwangaphambili lweentsinga zendalo (ezifana nomqhaphu kunye noboya) kunye neentsinga zokwenziwaushishino lwempahla olulukiweyo kunye nokudaya. Ukungcola okufana negrisi, i-wax kunye nesitashi zenzelwe ukuphelisa kwi-pretreatment. Uxinzelelo lwe-NaOH oluphezulu lunokubangela umonakalo ongenakuguqulwa kwiifibers ngelixa i-NaOH ephantsi yoxinaniso ingaphumeleli ukufikelela kwiziphumo ezilindelekileyo malunga nokupheliswa kokungcola. Ke ngoko, ixesha lokwenyani lokujongwa kweNaOH yinto efunekayo yokudaya egudileyo kunye neenkqubo zokugqiba ukuphucula ukufana kwedayi yelaphu kunye nokuguquguquka kombala.

Ukungaphumeleli kweTitration yeSiqhelo

I-Titration yeyona ndlela isetyenziswa ngokuqhelekileyo ukulinganisa ukuxinwa kwesisombululo se-NaOH, kwakhona indlela echitha ixesha kunye neyomsebenzi xa ithelekiswa ne-intelligent inline.imitha yobuninzi bolwelo. Ngaphezu koko, i-titration ayikwazanga ukubona utshintsho lwexesha lokwenyani kugxininiso kwaye yazisa iimpazamo ezenziwa ngesandla xa iimeko zokusebenza zitshintsha.

Ngapha koko, i-titration iyasebenza kuhlalutyo lwebhetshi kunokuba ihambelane ne-automation batching system ngexesha lokwenyani. Ngexesha elifanayo, akufanelekanga kwimilinganiselo yoxinzelelo oluphezulu. Abanini-zithuthi basesichengeni sokusingqongileyo enezinto eziguquguqukayo okanye eziyingozi ukuba kunokwenzeka ukongezwa okunokonakala okanye okuguquguqukayo kuwo wonke umgca wemveliso.

Uphuculo lwe-Batching echanekileyo kwiiNkqubo ze-Automation

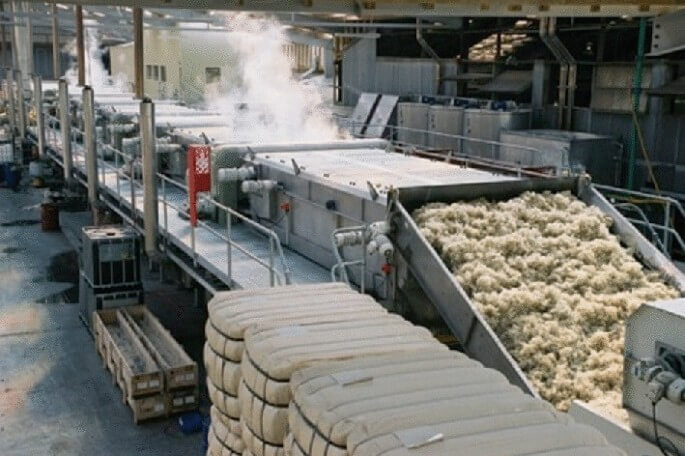

I-in-lineimitha yoxinzelelo lolwelo,eka aimitha yoxinzelelo lwenyukliya,idityaniswe kwiinkqubo ezizenzekelayo zempahla yelaphu kunye nokudaya ithatha iziphumo ekulandeleni iinkqubo zobugcisa ezifana ne-desizing, ukukhangela, i-mercerization, ukudaya, ukuprinta, njl.

Ukunciphisaii-agent ziyanyibilika emanzini ukuphelisa izixhobo zokulinganisa ukusuka kwiilaphu, ezifana nezisombululo ze-NaOH kwinqanaba elithile elenzelwe amalaphu athile. Iimitha yoxinaniso oluzenzekelayoiqinisekisa isisombululo esinqwenelekayo sihlala kuluhlu olufanelekileyo lokupheliswa ngokupheleleyo. Ithintela ukwenzeka kweengxaki zobugcisa ezinjengokudaya ngokungalingani kunye nokungonelanga ukwenza ideyizi, ukunciphisa iindleko zokuphinda kusetyenzwe kunye nokuphucula ukudaya kunye nokusebenza kakuhle koshicilelo.

Isoda yeCaustic kunye nezinye iikhemikhali zisetyenziselwa ukususa ukungcola kumalaphuukufumana. Ukudityaniswa okuchanekileyo kweekhemikhali kunokulungelelaniswa ngokuzenzekelayo ngokobuninzi bexesha lokwenyani okanye idatha yoxinaniso. Ngaloo ndlela, ubumhlophe belaphu, ukugqithiswa kunye nezinye izikhombisi zomelezwa kakhulu. Okwangoku, iyafana nenkqubo ye-mercerization.

Uxinaniso lwesisombululo sedayi sinokujongwa ngemitha yoxinaniso lwedijithali kulwelo ngexeshaukulungiswa kwedayi. Ivumela ulawulo oluchanekileyo lokugxilwa kwedayi, iqinisekisa ukufana kunye nokudaywa okuchanekileyo ngelixa unqanda ukuhluka kwemibala okubangelwa ukuguquguquka koxinzelelo lwedayi. Iimitha yoxinaniso lolweloiphucula isivuno sokuqala sokudaya, inciphisa iziphene, kwaye icuthe inkcitho. Iyasebenza ekujongweni koxinaniso lwencama yemibala ekulungiseleleni ukuncamathisela kombala.

Nceda uqhagamshelane neumvelisi ophambili iLonnmeterngoko nangoko ukubona ukuba imitha yoxinaniso olungaphakathi luyasebenza kumgca wakho wemveliso okanye hayi. Cela ikhowuti yasimahla ngoku!

Ixesha lokuposa: Jan-10-2025