I-polymer melt viscosity yokulinganisa imisela i-extrusion kunye nenkqubo yokubumba. Ukujongwa kwexesha langempela le-viscosity kubaluleke ngaphezu kobushushu kunye nokubeka iliso loxinzelelo.

Overvieweof ExtrthinanMoldingProcess

Ukubumba i-Extrusion yinkqubo esebenzayo yokuvelisa kumashishini amaninzi ukwenzela ukuveliswa kweeprofayili eziqhubekayo njengemibhobho, iifilimu, amashidi, njl njl. Ivumela ukuveliswa kweemilo ezinqamlekileyo ezinqamlezileyo kumgangatho ongaguqukiyo ngelixa iqinisekisa isantya esiphezulu semveliso kunye nokusebenza kakuhle kwezinto. Inkqubela phambili ecacileyo efana nenkqubo ezenzekelayo, ukujonga ixesha lokwenyani kunye nokubekwa esweni kwenkqubo yokurisayikilisha kuphucule ukuchaneka kunye nokunciphisa impembelelo yokusingqongileyo ngokunciphisa inkunkuma.

Rough Ii-DEA yeExturusikwiMachmna

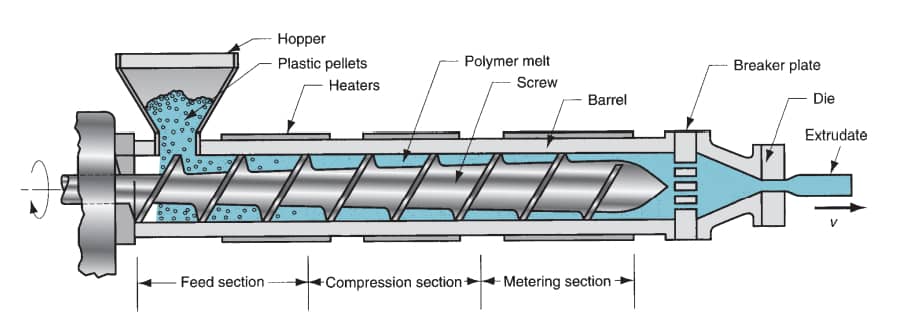

Umatshini we-extrusion unamacandelo alandelayo: i-hopper, i-screw yokondla, izinto zokufudumeza kunye nempompo yegiya. Izinto eziphathekayo zifakwe kumatshini kwi-hopper. Isikrufu sokutyisa esijikelezayo ngokuqhubekayo, esiqhutywa yinjini kunye nebhokisi yegiya, sihambisa imathiriyeli ecaleni komphanda nangedayisi. Izinto zokufudumeza ecaleni kombhobho zigcina amaqondo obushushu alawulwayo ukuze athambe kwaye anyibilike imathiriyeli yepolymer. Emva kokuphuma kwidayisi, into etyhidiweyo ingena kubumba kunye nomngxuma omnye okanye ngaphezulu, apho ipholisa kwaye iqine ibe yimo oyifunayo. Kwezinye iinkqubo, impompo yegiya ibekwe phakathi kombhobho kwaye ife ukuze kuqinisekiswe uxinzelelo oluhambelanayo kwizinto eziphumayo.

Amanqaku oMlinganiselo weViscosity aPhambili kuMatshini we-Extrusion

Ukuphuma kweHopper / Indawo yokutya: Ilinganisa i-viscosity yokuqala yokunyibilika njengoko ipholima iqala ukuthamba.

Indawo enyibilikayo (Mid-Barel): Ibamba inguqu ukuya kwimo yokunyibilika ngokupheleleyo.

Indawo yokulinganisa(Ngaphambi kweMpompo yeGear okanye iDie): Ilinganisa umlinganiselo we-viscosity ye-polymer phantsi kweereyithi zokucheba zokusebenza.

Ukufa kokungena: Ibonelela ngexesha langempela lokunyibilika kwedatha ye-viscosity kwindawo ye-extrusion.

Ukuqonda iPolymer Melt kunye neViscosity

Yintoni i-polymer melt?

Yipolymer eshushu kwimo etyhidiweyo, ebonisa iipropathi zokuhamba ezivumela ukubunjwa ngokukhupha okanye ukubumba. Inyibilika i-viscosity yeepolymers-ukumelana nokuhamba-kuxhomekeke kubunzima bemolekyuli, ubushushu, izinga lokucheba, kunye nezongezelelo, okuphembelela ukomelela nokugqiba kwemveliso yokugqibela. Kwiinkqubo yepolymer extrusion, apho i-polymer etyhidiweyo ikhutshwe ngokufa, kunye ne-injection yokubumba, apho igcwalisa ukubumba phantsi koxinzelelo, igcina ilungilenyibilika i-viscosityibalulekile. Ngokwemveliumlinganiselo we-viscosity we-polymeriindlela, ezifana ne-capillary rheometry engaxhunyiwe ku-intanethi, ihlala iqhwala ngenxa yokulibaziseka, ibangela ukuba utshintshonomgcaviscometer yeepolymersngolwazi lwexesha lokwenyani.

Imingeni kwi-Polymer Extrusion kunye noLawulo lweNkqubo

Iinkqubo yepolymer extrusionkunye nokubumba inaliti kujongana nemiqobo ebalulekileyo ekugcineni ingaguquguqukinyibilika i-viscosity. Ukwahluka ngenxa yokuthambeka kwe-thermal kunye nokuguquguquka kwamazinga okucheba kunokukhokelela ekungalinganininyibilika i-viscosity yeepolymers, ebangela iziphene ezifana nezitenxo zomphezulu okanye ii-voids kwiiprofayili ezikhutshiweyo. Imigca ye-extrusion emikhulu iyasokola kunye neyunifomuumlinganiselo we-viscosity we-polymerngaphaya kokuhamba, ukugcina ukuthotyelwa kulawulo lwenkqubo. Kwi-high-speed-speed injection molding, uhlengahlengiso olwenziwa ngesandla aluphumeleli ukuhambisana namaxesha omjikelezo okhawulezayo, umngcipheko we-warpage okanye ukuzaliswa okungaphelelanga. Le mingeni igxininisa imfuneko yokuqhubela phambilii-viscometer yepolymeriinkqubo, njengei-viscometer yepolymer ezenzekelayo, ukubonelela ngedatha yexesha langempela kwaye unqobe imida yeendlela zendabuko.

Kutheni Melt Viscosity Monitoring Matters

Umlinganiselo we-viscosity we-Melt ubalulekile kwinkqubo ye-polymer extrusion kunye nokubumba inaliti ngenxa yezizathu ezininzi. Kwi-extrusion, i-viscosity ye-melt engaguqukiyo iqinisekisa ukugcwala okufanayo kunye nokuthintela iziphene ezifana nezitenxo zomphezulu okanye ukudumba. Ekubunjweni kwe-injection, ichaphazela ukuzaliswa kwesikhunta, umgangatho wenxalenye, kunye nexesha lokujikeleza, apho ukuhluka kunokukhokelela kwi-warpage okanye ukuzaliswa okungaphelelanga. Ukujongwa kwexesha langempela kuvumela abaqhubi ukuba bahlengahlengise ukushisa, uxinzelelo, okanye ukubunjwa kwezinto eziphathekayo kwi-fly, ukwandisa ukusetyenziswa kwamandla kunye nokunciphisa inkunkuma-iinkxalabo eziphambili njengoko imimiselo yekhabhoni iqinisa ngo-2025.

Ubunzima bomlinganiselo we-polymer melt viscosity buvela kwindalo engeyiyo ye-Newtonian yokunyibilika kwe-polymer, apho i-viscosity iyahluka ngokwezinga lokucheba kunye nembali ye-thermal. Iinkqubo ze-inline polymer-melt viscometer systems zijongana nale nto ngokubonelela ngedatha eqhubekayo, ivumela ulawulo lwenkqubo ukuba iindlela ezingaxhunyiwe kwi-intanethi azikwazi ukuhambelana.

UbuGcisa beLonnmeter kuNyibilika iViscosity Monitoring

Ngaphezulu kweminyaka elishumi yamava,Lonnmeter, okhokelayoumthengisi we-polymer viscometer, uye wazimisa njengovulindlela kwiesweni viscosity. Ubuchwephesha babo bubandakanya uxinzelelo oluphezulu, imigca yobushushu obuphezulu kunye nezixhobo zokubumba iinaliti, ukujongana neemfuno zeepolymers ezahlukeneyo ezifana ne-polyethylene, i-polypropylene, kunye ne-PET.

Product Solutions

I-Lonnmeter ibonelela ngeyona ndlela iphambilii-viscometer ye-polymer enyibilikayoizisombululo ezenzelwenyibilika esweni viscosity. II-Viscometer engaphakathiyenzelwe ukufakwa kwe-perpendicular okanye i-parallel kwi-extrusion machines, ukulinganisanyibilika i-viscosityukuya kuthi ga kwi-100,000 cP·s kunye namaqondo obushushu ukuya kuthi ga kwi-300 ° C, engachatshazelwanga ziinguqu zokuhamba.

Ukwenziwa ngokwezifiso luphawu lweminikelo ye-Lonnmeter, enokhetho loqhagamshelo oludityanisiweyo okanye olune-flanged kunye nemveliso yedatha nge-4-20mA okanye i-RS485, idibanisa ngokungenamthungo kunye neenkqubo ezizenzekelayo. Kwi-extrusion, i-perpendicular setup iqinisekisa ukuphazamiseka okuncinci kokuhamba.

Izibonelelo zeLonnmeter's Melt Viscosity Solutions

Ukuqinisekisa umgangatho:Ixesha elilungileumlinganiselo we-viscosity we-polymeriqinisekisa i-extrudates engenasiphene kunye neendawo ezibunjiweyo.

Ukusebenza kakuhle kweendleko:Ukunciphisa inkunkuma kunye nokugcinwa kweendleko zokusebenza eziphantsi.

Ugcino lwamandla:Uhlengahlengiso oluchanekileyo longeza ukusetyenziswa kwamandla.

Inkqubo yokuguquguquka:Ukuhambelana neepolima ezahlukeneyo zixhasa iimfuno ezahlukeneyo zemveliso.

Ukhuseleko olomeleziweyo:Ukufunyaniswa kwangaphambili kwe-viscosity anomalies kuthintela ubunzima bezixhobo.

Ii-FAQs

Kutheni i-viscosity enyibilikayo ibaluleke ngakumbi kunobushushu okanye uxinzelelo?

I-Viscosity ye-Melt ichaphazela ngokuthe ngqo ukunyibilika kokunyibilika, ukuzaliswa kokufa, kunye nokuhambelana kwemveliso, ehlala igqithisa impembelelo yobushushu okanye uxinzelelo. Umlinganiselo we-viscosity we-polymer ofanelekileyo unqanda iziphene ezifana ne-warpage okanye ukudumba, oko kuyenza ibaluleke kakhulu kulawulo lwenkqubo.

I-Lonnmeter iqinisekisa njani ukudityaniswa kwedatha?

I-viscometer ye-polymer ezenzekelayo idibanisa nge-4-20mA okanye i-RS485 protocol, inikezela idatha yexesha langempela kwiinkqubo zokulawula. Imbali yayo ekwibhodi, efikelelekayo ngesoftware, ibonelela ngemibono yembali, yodlula imida yepolymer ye-viscometer yemveli.

Ziziphi izinto ezinefuthe kwi-viscosity yokunyibilika kweepholima?

Ukunyibilika kwe-viscosity yeepolymers kuphenjelelwa bubunzima bemolekyuli, ubushushu, izinga lokucheba, kunye nobukho bezongezo okanye izigcwalisi. Ubunzima obuphezulu bemolekyuli kunye namaqondo obushushu asezantsi ngokuqhelekileyo anyusa i-viscosity, echaphazela inkqubo ye-polymer extrusion.

Ukujongwa kwe-viscosity enyibilikayo lilitye lembombo lenkqubo ye-polymer extrusion kunye nenaliti yokubumba, ukuqinisekisa umgangatho kunye nokusebenza kakuhle. Ngobuchule obungqiniweyo beLonnmeter kunye ne-viscometer ephucukileyo yeepholima, abavelisi banokoyisa imiceli mngeni kulawulo lwenkqubo kunye nokwandisa imveliso. Cela ikhowuti namhlanje kulo mthengisi uthembekileyo wepolymer viscometer!

Ixesha lokuposa: Jul-31-2025